Source: How-To Geek

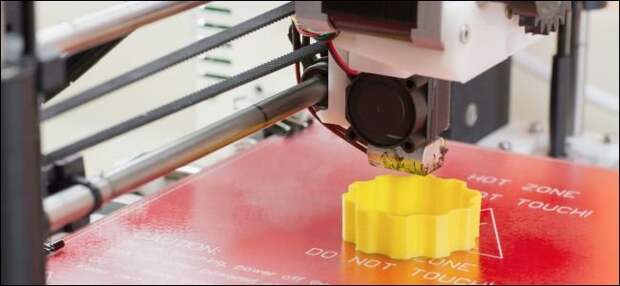

Picture a robot-controlled hot glue gun that uses plastic instead of glue, and you have the basics of a 3D printer. Strands of plastic are fed into a print head, which is heated up to melt the material. The print head moves around very precisely in three dimensions and drops lines of plastic onto the print bed—the table on which it prints.

The printer does this over and over, building up layers of plastic until it forms a 3D part.It All Starts with 3D Models

Every object printed on a 3D printer starts with a 3D model. These are usually made in a CAD program designed for working on real-world 3D models, like TinkerCAD, Fusion360, or Sketchup. This is a bit different to how 3D models might be made for movies or games, though you could certainly print out very detailed figures from traditional 3D modeling software.

One benefit of a 3D printer is that it can print nearly anything. Some models are so complex that they’re impossible to make with traditional manufacturing techniques like molding or CNC routing, and that’s where 3D printers take an obvious lead. However, they’re not just used for making fancy geometric shapes, as it’s usually much cheaper for a large factory’s R&D department to print a single model in plastic rather than rigging up the whole factory to make the actual part. This is called prototyping, making a rough draft to help test the final copy without wasting valuable time and materials.

Slicing the Model for the Print

Since a printer doesn’t understand how to take a complex 3D mesh and turn it into a printed model, the 3D model must…

The post How Does 3D Printing Work? appeared first on FeedBox.