Author: Jenny List / Source: Hackaday

When you grow up with something as the constant backdrop to your life, it’s easy to forget as an adult that not everyone else shares your instinctive knowledge of the subject. My dad is a blacksmith, he’s now retired, but as I was growing up his very active forge was in a workshop next to our house.

This is the second part of a series based upon that experience, exploring blacksmithing for people who have maybe always fancied a go at the anvil but have little idea where to start.The Most Obvious Blacksmithing Tool: The Anvil

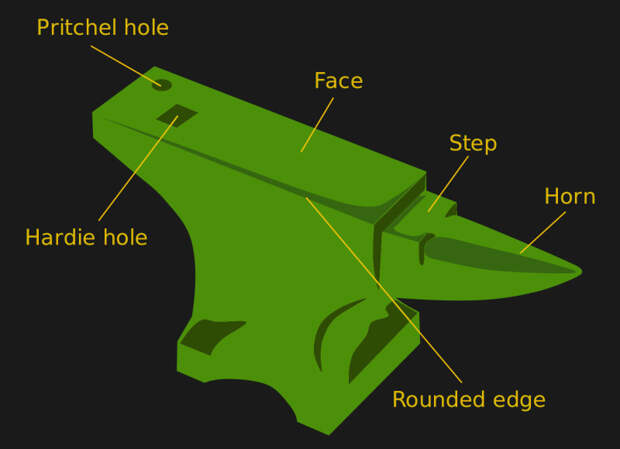

Having considered the hearth in our previous outing, it’s time to turn our attention to what is the signature piece of blacksmithing equipment: the anvil. This has the function of providing a high-mass hardened working surface against which metal can be forged, and it has a distinctive shape with various parts for particular metalworking tasks. There are many minor and major variations of anvil design depending upon where in the world your anvil hails from, but since my experience comes from the English counties, the anvil I will be describing is the pattern you’ll find in the British Isles.

A blacksmith’s anvil is a large block of iron, which is to say forged steel or in some much older anvils wrought iron, but sometimes and usually in cheaper anvils, cast iron. It has a flat rectangular top surface for working metal referred to as the face which is made of hardened steel, on many anvils this can be a separate piece welded to the top of the body of the anvil. At one end of the face is a conical tapered point referred to as the horn which is used to form curves, and at the other is as squared-off edge referred to as the heel, which tapers away underneath towards the base of the anvil. In the face towards the heel are usually two holes, a large square opening called the hardie hole which is designed as a receptacle for tooling, and a small round one called the pritchel hole which is designed as a place to use a punch or similar tool on a piece of work without damaging the face of the anvil. You will sometimes see anvils with different shapes, perhaps with protrusions on their sides or with a horn at each end, these will either be of an overseas pattern or designed for a specific task such as shoeing horses.

Your Hammer Will Know the Difference

There is a “feel” to a good quality anvil, if you strike it with a hammer. This is something that you will understand from experience once you have tried it, but on the ideal anvil there would be a ring sound and the hammer would rebound as though bouncing. It’s a good indication of the quality of a surface for use as an anvil, and it’s one you can readily appreciate if you test a few surfaces. Compare the note and feel of a hammer blow to a good anvil with that of hitting a piece of cast iron such as a scrap engine block, or hitting a piece of steel, and what you will learn will help you judge the quality of any anvil you consider.

The post Blacksmithing For The Uninitiated: Let’s Talk About Anvils appeared first on FeedBox.