Author: Tom Nardi / Source: Hackaday

A video has been making the rounds on social media recently that shows a 3D printed “steak” developed by a company called NovaMeat. In the short clip, a machine can be seen extruding a paste made of ingredients such as peas and seaweed into a shape not entirely unlike that of a boot sole, which gets briefly fried in a pan.

Slices of this futuristic foodstuff are then fed to passerby in an effort to prove it’s actually edible. Nobody spits it out while the cameras are rolling, but the look on their faces could perhaps best be interpreted as resigned politeness. Yes, you can eat it. But you could eat a real boot sole too if you cooked it long enough.To be fair, the goals of NovaMeat are certainly noble. Founder and CEO Giuseppe Scionti says that we need to develop new sustainable food sources to combat the environmental cost of our current livestock system, and he believes meat alternatives like his 3D printed steak could be the answer. Indeed, finding ways to reduce the consumption of meat would be a net positive for the environment, but it seems his team has a long way to go before the average meat-eater would be tempted by the objects extruded from his machine.

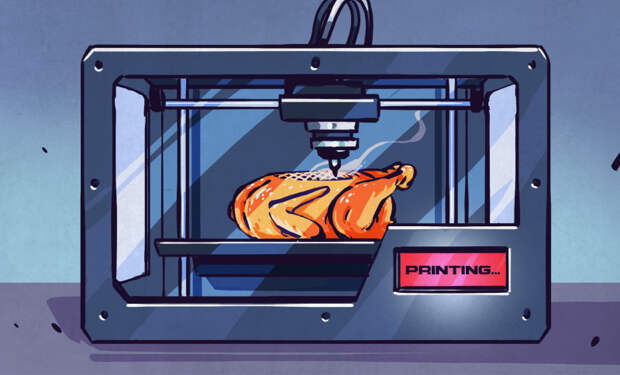

But the NovaMeat team aren’t the first to attempt coaxing food out of a modified 3D printer, not by a long shot. They’re simply the most recent addition to a surprisingly long list of individuals and entities, not least of which the United States military, that have looked into the concept. Ultimately, they’ve been after the same thing that convinced many hackers and makers to buy their own desktop 3D printer: the ability to produce something to the maker’s exacting specifications.

A machine that could produce food with the precise flavors and textures specified would in essence be the ultimate chef, but of course, it’s far easier said than done.Customized Cuisine

It should be said that there’s no magic when it comes to printing edible objects. It’s something that we’ve seen done many times at the hobbyist scale, from homebrew machines to the occasional official accessory for a commercial desktop 3D printer. At the absolute basic level, you simply replace the existing extruder and hotend with a syringe full of some sort of edible paste: peanut butter, dough, frosting, whatever.

So far, it seems like the most headway has been made with chocolate because it has certain properties not entirely unlike the thermoplastic filament desktop 3D printers are designed for. If you warm it…

The post 3D Printering: The Quest for Printable Food appeared first on FeedBox.