Author: Larry Cotton / Source: Make: DIY Projects and Ideas for Makers

So your Aunt Harriet brought you a big sack of pecans from her farm — awesome! Only one small catch: you get to shell them. No way are we going to do this manually with a “pliers” style nutcracker, right?

One alternative is to buy the legendary Texas Native nutcracker from Amazon or eBay for about $50.

While this rubber band-powered relic from about 40 years ago does work, ask anyone who’s cracked more than a dozen pecans with it how long it took for their left thumb to heal.There are several semi-automatic, one-pecan-at-a-time crackers on the market. All work using the same principle as the Texas Native: by bashing the pecan from one end, causing a weight at the other end to move a bit, with considerable resisting inertia. They can be bought for a paltry $200–$400 from vendors like Red Hill General Store. And you still have considerable follow-up picking to do.

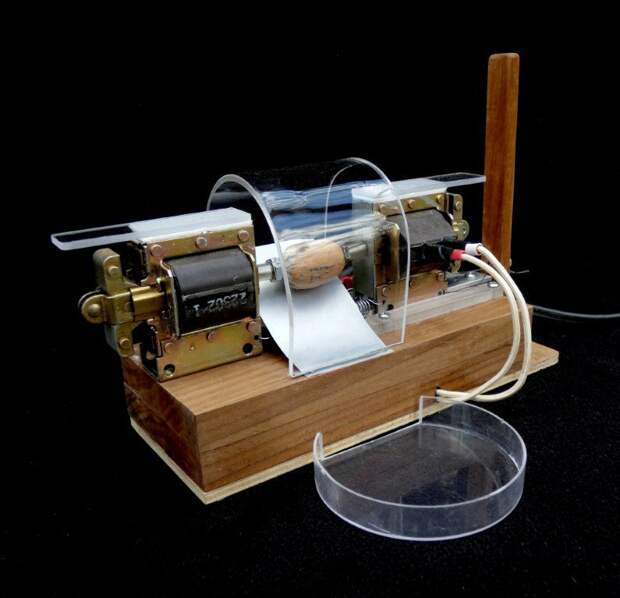

The Pecan Blaster uses the same basic principle, but with two heavy-duty 115-volt appliance solenoids facing each other. Just load a pecan between the solenoids and close the clear protective shield to fire both solenoids simultaneously. The pecans don’t stand a chance when bashed from both ends. The left solenoid is fixed, but the right one slides to accommodate various size nuts* and kicks back somewhat, using the inertial weight principle of the old-style crackers. Both halves of the nut usually survive unscathed and separated from most of the shell; the rest of the time I get quarters and smaller pieces, which are fine for most baking or snacking purposes.

Most cracks need no further shelling.Here’s how you can build one like mine, but feel free to use alternate materials and slightly different measurements than what I chose.

BUILD THE BASHERS

1. Buy your solenoids from Electronic Goldmine, item #G20264B, the cheapest I could find that would do the job. Two of these babies cost under $10. EG’s got a $10 minimum, so look around for something else to add to your order.

Or, if you really want them in two days, Amazon has them for around $25 each (plus shipping), item #B01MQ4H6OP.

2. Make a base from an 8″ length of 2×4. I happened to have some walnut, and of course it would be slick to use pecan! (Ask Aunt Harriet if you can cut a limb off one of her trees.) With a band saw or circular saw, cut a wiring slot about 1/8″ wide across the bottom, about 2¾” from one end.

3. Prepare the solenoids. They’re designed to pull, but they must push. So carefully drill, with a drill press, a 1/8″ hole in the center of each solenoid in the plain side.

The hole is 1″ down from the top, all the way through the approximately 1/4″ wall. Use a center punch for accuracy! Each hole must be in line with its respective internal plunger. Carefully widen the hole to ¼” using several bits from 1/8″ to 1/4″.

After drilling, carefully blow, brush, and/or wash out with solvent (such as paint thinner; not water) any chips that fell into the solenoid. A magnetized screwdriver tip can help as well. Slide a ¼”-20 or ¼”-28 bolt back and forth through the solenoids’ holes until they offer no resistance.

While you’re at it, also drill two 3/32″ holes in the end of each solenoid to hold the ends of springs as shown in Step 8.

4. Mount one solenoid on the base’s top, at the opposite end from the wire slot. It will be on your left as you use the Blaster and should be on the centerline, flush with the end of the 2×4. Keep it parallel to the long sides, with the solenoid’s plunger hanging off the end of the base.

Mount it by drilling slightly oversize holes through the base to match the hole pattern in the solenoid. I used two 1¾” 8-32 machine screws, nuts, and toothed washers; tighten that sucker down.

5. Mount the other solenoid at the right end. It will slide back and forth, from about 2″ away from the left solenoid to about 3½” away. Its plunger must be to the right. This solenoid must be guided to slide smoothly and accurately with minimum friction. I made 3 rails: two side rails from ¼” acrylic (such as Plexiglas) and a center rail from 1/8″×5/8″ aluminum strip.

The center rail’s ends must be elevated 1/8″ to prevent binding. I made two 1/8″×¾”×¾” acrylic spacers, which double as limit stops. Mount them so that the right solenoid moves smoothly back and forth without excessive play, and stops about 2″ from the left solenoid at their closest positions. Travel distance will be about 1½”. Later, two springs will connect the two solenoids.

6. I made the pecan holders/bashers from ¼”-20 bolts (¼”-28 is OK, too). Use 2 bolts with at least 11/8″ of smooth, unthreaded length. Cut them with a hacksaw, and file the ends smooth so they’ll easily go into the solenoids.

The heads need a conical recess to properly locate the pecans. With a drill press and vise, clamp each bolt and drill a 1/8″ hole in the center of its head (use a center punch) about 1/8″ deep. Switch to a 45° or 50° angle, ½” diameter (minimum) countersink bit, and countersink over the drilled holes until the diameter of the conical shape is 5/16″–3/8″ at the tops of the bolts.

7. I made bolt-head spacers out of a ballpoint pen housing (think cheapest Paper Mate), about 7/16″ long. They should fit snugly over the bolts. If not, hot-glue them in place under the heads.

Poke the two bolts into the solenoid holes — they must slide in freely — and bring the solenoids as close as they can go together (about 2″, remember?). The bolt heads should now be in line with each other, about ¾”–7/8″ apart at their closest. In addition, when both bolts are pushed in until their spacers hit the solenoids’ laminations, the gaps between the outsides of their laminations to their plungers must be around ¼”. This is the distance each solenoid would/could/will push its plunger (depending…

The post Pecan Blaster: A High-Power Inertia Nutcracker appeared first on FeedBox.