Author: Lewin Day / Source: Hackaday

Recently, I was lucky enough to receive a big haul of retro computer gear from a friend who was emptying out his garage. Even better, the haul was almost entirely old Amiga gear — my favorite computing platform of all time. Upon returning home, I gleefully sorted through the boxes, powering things up one by one.

Amazingly, everything worked… except for one lonely Amiga 500+. I was greeted by a dull grey screen. This wouldn’t do, so naturally, I got to work.It seemed like a shame to be opening the machine, as after almost 30 years of life, this one still had its warranty seal intact. Regardless, nothing ventured, nothing gained – the Torx bits were at hand and the screws were coming out.

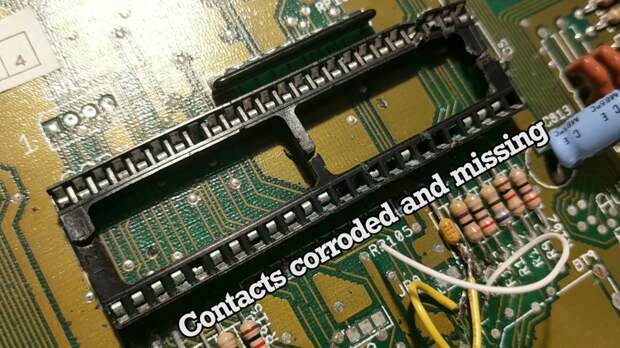

Inside, I found much what I’d expected. The electrolytic capacitors were all clean and holding up well, but there was significant corrosion caused by the clock battery. It was thankfully localised to a small cluster of traces near the Gary chip, which provides glue logic and floppy drive functionality. Looking closer, I also noticed that Gary himself was looking rather corroded. Commodore were kind enough to socket the custom chips on all Amiga boards, so I popped it out – only to find that several contacts in the socket had broken or corroded away.

The job was looking like a frustrating, yet achievable one. I cut the battery off, then began patching the traces. One by one, I traced out where they were supposed to go, then scraped back a small amount of soldermask in order to have copper to solder to.

Then, a thin patch wire was tacked in place to restore the connection, before verification with the multimeter.Fixing the Gary situation was going to be more difficult. The entire socket would have to be removed. I cut the socket away pin by pin, so I could deal with each one individually. Patience is the name of the game here, as being too rough in removal can lead to damaged vias or traces. I used a spring-loaded solder sucker to remove as much of the solder as possible from each pin, and then heated the via once more while pushing the remains of the pin out with a toothpick. I found this technique to be relatively successful, far more so than former attempts using metal wire as a pusher. The hardest pins are always those with connection to the ground plane – there are no thermal reliefs, so the solder sucker doesn’t work particularly well there. With perseverance, I was able to remove all the old pins, and solder in a fresh socket for Gary. At this point, I felt accomplished. I’d solved the obvious problems on the board, and thus would clearly be rewarded with a working machine.

Alas, it is rarely so simple. Upon powering up the machine, the screen was wavy, lacking any video sync, except to occasionally flash up a solid colour now and then. Blue, red, green – these are all various error codes the Amiga can display. It seemed unlikely I was suffering all of them, but I was…

The post Resurrecting An Amiga 500+ appeared first on FeedBox.