Author: Kerry Scharfglass / Source: Hackaday

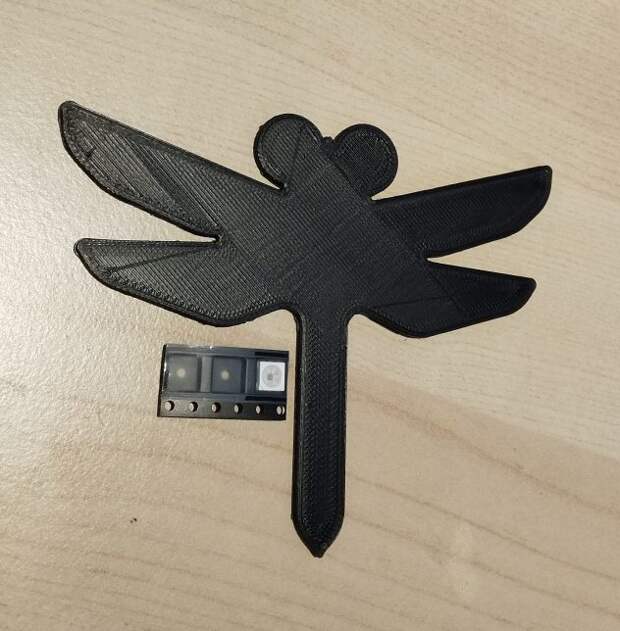

A couple years ago I got into making electronic conferences badges by building a device for DEFCON 25 shaped like a dragonfly. Like all badges the most important design factor was quite literally how flashy it was, and two years ago I delivered on that with ten RGB LEDs.

At the time I planned to hand-assemble each and every of the 105 badges at my kitchen table. Given those constraints, and a desire for electrical and programmatic simplicity, I landed on using APA102s (DotStar’s in Adafruit parlance) in the common 5050 sized package. They were easy to place, easy to design with electrically, simple to control, and friendly to a human pick-n-place machine. Though by the end of the production run I had discovered a few problems, the APA102s were a success.This year I made a new and improved version of the dragonfly, but applying my lessons learned led me to choose a very different LED architecture than 2017. I swapped out the smart LEDs for dumb ones.

When starting a new project I find it’s helpful to to clearly articulate a goal. In the first year the goal was “learn about building more than one of something”, a skill that can be quite a struggle! This year’s goal was “learn how to do things as if I was building a product for real.” Fortunately it turns out I’m not the only one around here who’s interested in that process and I had a lot to learn. To meet that goal the plan was to build 500 badges and get them manufactured and assembled by a real overseas production facility, a process which warranted new design considerations.

Let’s do some quick math. In 2017 each APA102 cost me $0.13 (purchased on eBay) and each unit had 10 of them, so that’s $1.30 in LEDs per badge. Not bad! The LEDs were pretty much the headline feature of the device and it was worth some money to do it right. But this year I obviously needed more LEDs. Last time I was bound by the practical reality of hand placing every LED which put a hard limit on the number of parts per board I was willing to use, but for 2018 I had already decided this wouldn’t be the case. So how many LEDs should I use?

Obviously I should aim for a couple hundred! Well…as you can see in the image on the right a hundred LEDs won’t fit. How many will? After some non-scientific playing with a printed mockup of the design it seemed like with some adjustments maybe around 50 would. There would be plenty of time to tune the number as I went so it was more important to begin estimating than it was to be exactly right at the start. If I used the same of APA102s at the same price (remember, this is a rough estimate) I was looking at about 50 * $0.13 = $6.50 of LEDs per board. Again, for the headline feature, not too bad. But maybe I could do better. Now that adding LEDs was basically free in terms of assembly time I wanted as many as I could get.

What about “dumb”…

The post When are Dumb LEDs the Smart Choice? appeared first on FeedBox.