Author: Charles Platt / Source: Make: DIY Projects and Ideas for Makers

If it runs a little too fast or slow, there’s no way to adjust it. An hourglass is a beautiful object, but it has problems. Sometimes the sand inside clogs up when two particles try to enter the neck side by side, and you have to shake it to start the sand flowing again.

Even when it’s working right, a typical palm-sized hourglass has to be turned upside-down repeatedly to measure intervals beyond a couple of minutes.I decided that a redesign was overdue.

CONCEPT

My first step was to change the name. I wasn’t going to be measuring hours, and I wouldn’t try to work with glass, so I called my gadget a Time Tube.

To prevent particles from clogging, I adopted the radical concept of using just one particle. Of course a single falling particle can only measure very brief intervals of time, but when you drop a magnet through a copper or aluminum tube, it falls surprisingly slowly as a result of creating eddy currents. (See “Dropping the Ball” on page 31.) Actually a 5/8″ spherical neodymium magnet will descend at about 9 inches per second, after which the tube must still be turned upside-down, hourglass-style — but I would use a motor to take care of that.

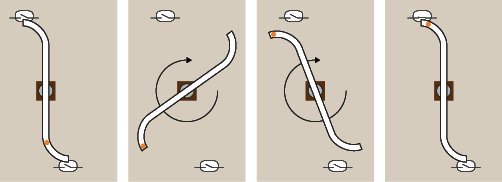

Above is a diagram of the concept. As the ball reaches the bottom of the tube, its magnetic field closes the contacts of a reed switch. (You can learn more about reed switches in my book Make: Electronics.) The reed switch triggers a relay, which starts a motor. The motor rotates the tube 180°, and the magnetic ball trips another reed switch, which shuts off the motor.

The ball falls through the tube again, and the cycle repeats.

The lower reed switch, or the pushbutton in parallel with it, will energize Relay B, pulling its movable contacts downward. (Some relays move the contacts in the opposite direction — check your datasheet to make sure.) In my schematic, the right-hand contacts start the motor while the left-hand contacts cause the relay to continue energizing itself even when the reed switch opens.

The motor keeps running until the upper reed switch triggers Relay B, opening its contacts, which are normally closed. This shuts off Relay A, so the motor stops while the ball starts to fall.

MATERIALS AND FABRICATION

I decided that my first Time Tube would just be a proof-of-concept design, to keep things simple. I wasn’t sure of the optimal magnet size, so I chose one that’s 5/8″ in diameter, to fit inside an aluminum tube of 1″ external diameter, with walls 1/8″ thick, allowing a 3/4″ internal diameter. Tubing of these dimensions is very easy to find.

I used a piece of tube only 9″ long, so that I wouldn’t need an elaborate structure and a large motor. Also, a short tube would be easier to photograph.

I cut a slot along the length of the tube to reveal the ball as it falls. If you do this, I suggest using an abrasive wheel on a handheld circular saw. Clamp two strips of wood horizontally on either side of the tube to support the saw while it slides along. Apply the clamps very firmly, wear eye protection, and do not use a wood-cutting blade!

Imagine a piece of 1″x18″ tube resting on workbench. Place a block measuring 1″ high, 18″ long, 2″ wide, beside the tube, parallel and touching. Another block on the other side, likewise. Apply clamp resting horizontally on the workbench crosswise, clamping the two blocks and the tube as a sandwich. Another clamp the other end, same. Now the saw can slide on the blocks with the blade dipping into the tube. The clamps are too low to get in the way. But there is still the problem of the clamped assembly shifting. Many workbenches allow you to insert a peg as a stop. Alternatively you could rest a 3-foot piece of 1×4 across the bench and clamp it into place, with the clamps far enough apart to allow the saw to slide between them. The 1×4 now stops the tube assembly from sliding.

Now you need to cap each end of the tube with a short piece of PVC pipe, curved so that when the tube rotates, the ball won’t fall again until the tube is vertical. You can use off-the-shelf PVC elbows from the plumbing department…

The post Reimagine The Hourglass — With Falling Magnets Slowed By Eddy Currents appeared first on FeedBox.